In today's fast-paced world, organizations are constantly seeking ways to enhance their efficiency and productivity. The 5S principles, derived from Japanese management practices, provide a framework that not only organizes the workspace but also fosters a culture of continuous improvement. This methodology emphasizes the importance of maintaining processes to ensure smooth operational flow and sustainable success. By implementing the 5S principles—Sort, Set in order, Shine, Standardize, and Sustain—companies are empowered to create a work environment that promotes accountability and engagement among employees. In this article, we will delve deeper into what it means to keep a process going in the context of the 5S principles.

Understanding how these principles interconnect is essential for leaders who aspire to cultivate a workplace centered around efficiency. Each of the 5S principles contributes uniquely to the operational framework, reinforcing the idea that a well-structured process is vital to organizational success. By keeping processes ongoing, businesses can minimize waste, optimize resources, and ultimately drive profitability.

Furthermore, grasping the significance of sustaining processes is crucial for long-term growth. It is not enough to implement these principles; organizations must also instill a sense of ownership and responsibility among their employees. This journey towards maintaining a seamless workflow is what we will explore through the lens of the 5S principles.

What Are the 5S Principles?

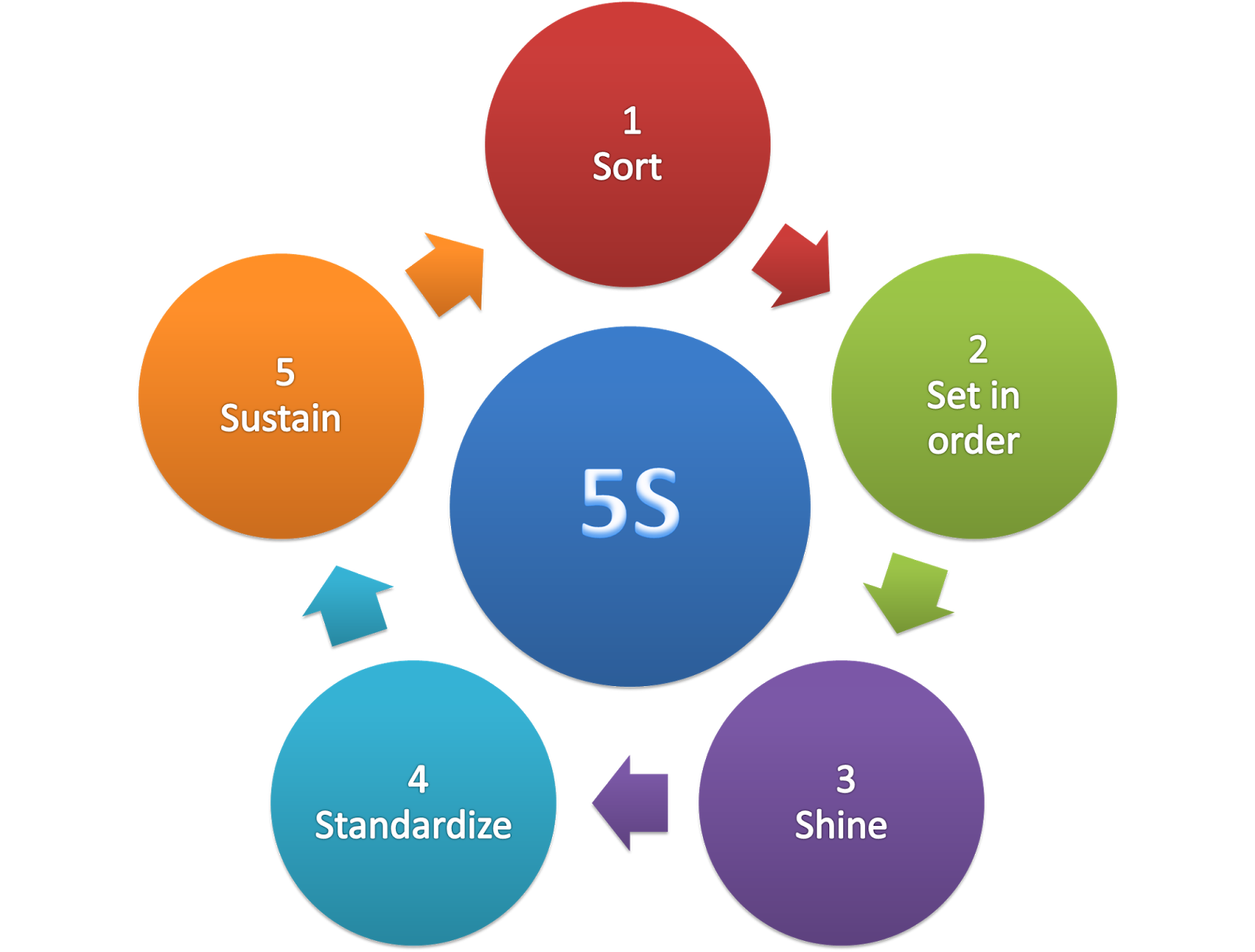

The 5S principles are a set of methodologies designed to improve workplace efficiency by fostering a more organized and disciplined environment. They include:

- Sort: Identify and eliminate unnecessary items from the workspace.

- Set in order: Organize tools and materials for easy access and use.

- Shine: Keep the workspace clean and tidy to promote safety and efficiency.

- Standardize: Establish procedures to maintain the first three S's.

- Sustain: Implement disciplines to ensure continuous adherence to the 5S practices.

How Does “Sustain” Keep Processes Going?

In the context of the 5S principles, “sustain” means to keep a process going by embedding the practices into the organizational culture. This involves regular training, audits, and reminders that reinforce the importance of maintaining an organized workspace. By fostering a culture of continuous improvement, organizations ensure that the benefits of the initial 5S implementation are not only retained but also enhanced over time.

What Are the Benefits of Sustaining Processes?

There are numerous advantages to sustaining processes within an organization:

- Increased efficiency and productivity.

- Enhanced employee morale and engagement.

- Reduced waste and operational costs.

- Consistent quality of products and services.

- Improved safety and reduced risks.

Can Sustaining Processes Lead to Long-Term Success?

Absolutely! Sustaining processes is integral to achieving long-term success. In the context of the 5S principles, organizations that prioritize sustaining their processes are better positioned to adapt to changes in the market and improve their operational capabilities. This adaptability helps them stay competitive and resilient in an ever-changing business landscape.

What Role Do Employees Play in Sustaining Processes?

Employee involvement is critical in the context of the 5S principles. When employees understand the purpose behind the 5S methodologies, they are more likely to take ownership of their workspace and contribute to sustaining processes. Continuous training, feedback mechanisms, and fostering a culture of accountability will empower employees to maintain the standards set forth by the 5S principles.

How to Measure the Effectiveness of Sustained Processes?

To ensure that processes remain effective and beneficial, organizations must implement measurement systems. Key performance indicators (KPIs) such as productivity rates, waste reduction, and employee satisfaction surveys can provide insights into the effectiveness of sustained processes.

In the Context of the 5S Principles, How Can Organizations Stay Committed to Sustaining Processes?

Commitment to sustaining processes requires consistent effort and a strategic approach. Organizations can utilize the following strategies:

- Regular Training: Provide ongoing training sessions that emphasize the importance of the 5S principles.

- Frequent Audits: Conduct regular audits to assess compliance and identify areas for improvement.

- Encourage Feedback: Create channels for employees to share their insights and suggestions on maintaining processes.

- Celebrate Successes: Acknowledge and reward teams for their efforts in sustaining processes to boost morale.

What Challenges Might Organizations Face in Sustaining Processes?

Despite the numerous benefits, organizations may encounter challenges in sustaining processes. Some common hurdles include:

- Employee resistance to change.

- Lack of management commitment.

- Inadequate resources for training and implementation.

- Failure to recognize and address the evolving needs of the organization.

Conclusion: The Importance of Sustaining Processes in the 5S Framework

In the context of the 5S principles, sustaining processes means to keep a process going, ensuring that the efforts made to improve efficiency and productivity are not only maintained but also refined over time. By embedding the 5S principles into the organizational culture, companies can create a work environment where processes thrive, ultimately leading to long-term success and a competitive edge in the marketplace.